From the Space Race to visions of life on Mars, rockets have fascinated humanity for decades. The sheer enormity, captivating takeoffs and landings and intricate designs seem to underscore one common theme: our desire to push the boundaries of exploration and conquer the unknown.

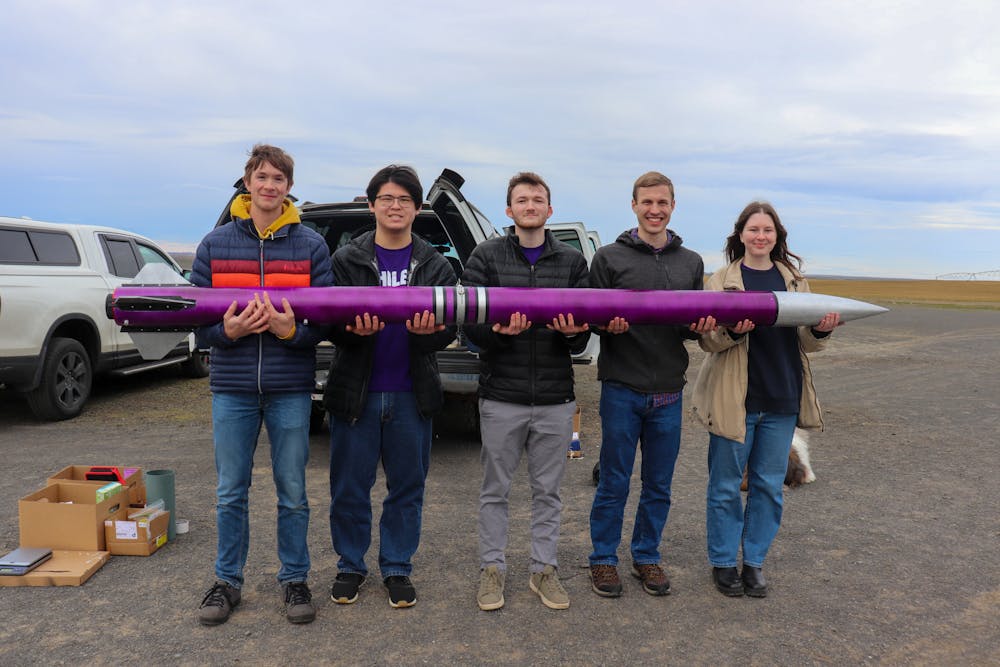

While they may not be sending rockets to other planets, five Capstone students within the Shiley School of Engineering are building their own for the NASA Student Launch Challenge, a competition between teams across the U.S. at collegiate and middle and high school divisions. The group, titled LaunchUP, joins 48 other collegiate teams in this year’s competition. They offer just one of a plethora of design choices in building the rocket from scratch.

“I remember one day [Professor Hainley] was like, ‘Do you guys actually really want to do this?’” team member Nick Warren said. “‘Because if you do, I’ll sign you up. I’ll make it happen.’ And we were like, ‘Yes.’”

With a series of launches already performed, the team will be bringing its rocket to Huntsville, Alabama for its final launch on April 13. This will include the full-scale rocket, which the team built after subscale testing was performed earlier this academic year.

Team members assembling internal components to the rocket. Photo courtesy of LaunchUP.

The rocket must reach a maximum altitude between 4,000 and 6,000 feet. Teams select an altitude in that range and then work their designs to be capable of reaching that goal. LaunchUP, for example, selected 5,000 feet as their anticipated maximum altitude for their 35-pound rocket, according to team member Connor Shannon.

The competition teams are tasked with more than just launching the rocket; they must abide by NASA’s challenge requirements that shift from year to year with regards to the rocket’s payload, which is housed inside of the body of the rocket, and its functionality.

Last year, for example, the payload consisted of a rotating imaging system that could detect landing conditions for the rocket. This year, the payload must eject within the 500 to 800-foot altitude range during the rocket’s descent. Content inside that payload must not be damaged by the falling impact from that height, and the team has a unique metric for testing that criteria.

“We just put four Lego figures in there and they’re supposed to represent human crew members,” Shannon said. “We just have to record the data like temperature [and] acceleration.”

Staging the rocket prior to a test launch. Photo courtesy of LaunchUP.

While the immediate solution might be to use a parachute, Shannon — whose primary role on the team focuses on the payload portion of the rocket — emphasized how NASA’s requirements don’t allow this. Rather, he and his teammates had to engineer a way to minimize the impact force from the ground on the payload.

“The creative solution we came up with was using helicopter blades,” Shannon said. “We kind of fold them alongside the payload so that they fit in the rocket. Once the payload is ejected, the blades will come out and unfold and spin. It’s not powered at all.”

While a parachute might not be usable for the payload, other sections of the rocket will need parachutes. For those to deploy and the payload to be individually ejected, the rocket must separate via the use of black powder charges, a low explosive material. This will cause the rocket to split into parts while still being tethered together by a shock cord, allowing the entire body to be reassembled after a launch.

Team members loading up a middle section of the rocket, which is designed to break apart during descent. Photo courtesy of LaunchUP.

Because of the explosive aspect, various safety regulations are put in place for the rocket to launch. While NASA restricts students from handling the black powder, LaunchUP found a competition mentor through the Oregon Rocketry Club who is allowed to do this given his various levels of security clearances through the rocketry club.

“[John] has been a huge part of why [LaunchUP] has been able to be successful, through giving [the team] advice and working with [the team] to build,” Shannon said.

Launches prior to the event in Alabama have been performed in remote areas for safety purposes. One subscale test, for example, required the team to travel to Brothers, Oregon, where the rocket was launched in a field.

Stability of the rocket is also a concern once it is launched given the various landing parameters set forth by NASA in their requirements. Additionally, the team has had to make past adjustments to smaller components that make up the rocket.

“We had a tiny epoxy failure during our subscale launch where just one of the components didn’t have enough epoxy on it and peeled off,” Warren said. “Luckily it was no big deal and the structural integrity was fine, but we’re trying to be cautious about the interfaces between things bonded together for the full scale [rocket].”

With the time consuming nature of the project and the countless pages submitted by the team to NASA over the past months, the members have taken pride in their work and are hopeful for successful outcomes on the April 13 launch.

Michael Lang is a member of the editorial board. He can be reached at langm24@up.edu.